VP-500/2S double chamber vacuum sealer is a kind of packaging machine, which uses its vacuum chamber to evacuate the packaging, and then fills in inert gas to achieve the purpose of anti-corrosion and quality assurance. The fully automatic double chamber vacuum packaging machine is specially designed for packaging products with high water content. It adopts Japanese control circuits and absorbs advanced technical experience in the same industry abroad. Its electrical aspects are controlled by microcomputer controller throughout the process. It is waterproof, moisture-proof, and failure rate. Low power, long service life and other advantages, these advantages make the equipment easy to clean, even if it is directly washed with water, no electrical failure will occur. The design can ensure that the water in the product does not lose, so that the water-containing vacuum packaging of the product is easier to operate.

It is suitable for flexible packaging materials such as plastic composite thin wax or plastic aluminum foil bags and anti-static bags. Vacuum packaging for solid, liquid, powder, paste electronic products, circuit boards, SMT patch trays, toys, tea, food, fruit, chemical products, electronic components, precision instruments, etc. The packaged product can prevent oxidation, mildew, corruption, moisture, vibration, and can keep the quality and freshness and prolong the storage period of the product.

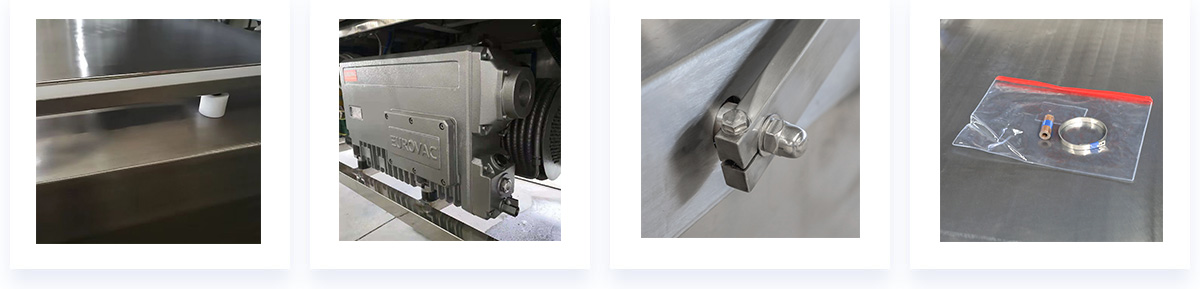

● The operating system is fully sealed, safe and reliable.

● Low friction lid motion for minimal opening and closing effort.

● Chambers and working bench are made of SUS 304 with 4mm thickness.

● Improved transformer and heater, longer service life, more beautiful and reliable sealing effect.

● Designed to meet CE requirements.

| Model | VP-500/2S |

| # of seal bars | 2 |

| Seal Length (mm) | 500 |

| Distance Between Bars (mm) | 410 |

| Chamber Size (LxWxH mm) | 590x540x115 |

| Seal Speed | 3-4 times/min |

| Vacuum Pump | Universtar(40m3/h) |

| Power (KW) | 0.75 |

| Electrical | 380V 3Ph 50Hz |

| Dimensions (LxWxH mm) | 1200x760x900 |

| Machine Weight(kg) | 150kg |