Consumption of fresh food and meteorological and soil environment, picking process, packaging process, packaging scheme and circulation and transportation environment (temperature and humidity range, performance parameters of cushioning pad and transportation packaging, circulation tools, road grade, vibration frequency), sales process and other factors are all related. Among them, packaging technology and solutions run through the entire supply chain of fresh food, and play a vital role in food preservation. Packaging technology - modified atmosphere packaging technology has gradually entered the public's field of vision.

What is MAP?

Modified atmosphere packaging: change the composition of the gas inside the package by gas replacement, that is, artificially increase or decrease the concentration index of the gas in the internal atmosphere or empty some gas, so that the food inside is different from the air composition (air is basically Composition ratio: nitrogen 78%, oxygen 21%, carbon dioxide 0.031%, rare gas 0.939%, other gases and impurities 0.03%) environment, by preventing and weakening the production of chemical or biochemical reactions in the food in order to achieve food freshness And to prolong the shelf life, the gas components inside the packaging container usually include one to three. In addition, another commonly used packaging process in fresh food - vacuum packaging technology is also called decompression packaging. In a narrow sense, vacuum packaging does not belong to the branch of modified atmosphere packaging, but belongs to the category of physical packaging technology, and has become an independent system with the deepening and evolution of technology. After removing the air from the packaging container, the interior of the container reaches a preset vacuum degree, and then the container is closed. But from a broad perspective, modified atmosphere packaging also includes vacuum packaging.

Three commonly used gases in modified atmosphere packaging

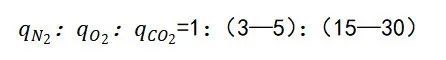

First of all, the methods of judging whether fresh food is fresh or spoiled in daily life mainly include "seeing, hearing and asking". Look: observe the color and appearance of the food; smell: smell the smell of the food; ask: ask about the basic information of the food; cut: touch the food to judge its integrity. These methods mostly appear in the sales and delivery stages of fresh food, that is, human identification. As far as the modified atmosphere packaging technology is concerned, the internal replacement gases mainly include carbon dioxide, carbon monoxide, oxygen, nitrogen, sulfur dioxide, and existing research results show that some argon can be selected in an appropriate amount for certain fresh products. However, the three most commonly used replacement gases for fresh food are still: nitrogen, oxygen, and carbon dioxide. The specific ratio concentration, whether they coexist, and the functions in the components of the three will all change with the physiological characteristics of fresh food and the reasons that can cause deterioration.

Oxygen. In general, oxygen is closely related to respiration. The existence of oxygen in modified atmosphere packaging means food oxidation and the reproduction of aerobic microorganisms, which are unfavorable factors for food spoilage and should be excluded from the gas components. The water activity Aw of the food is introduced here. Water activity measures the free water molecules in food, which are the supplies for the survival and reproduction of bacteria and microorganisms. The cause of food spoilage is the chemical reaction, enzymatic reaction, and microbial growth and reproduction that occur inside it. Therefore, inhibiting water activity will effectively control food quality. For foods with water activity below 0.88, deoxygenation can greatly extend the shelf life; and for fresh foods with high water activity, deoxygenation also plays a certain role in freshness preservation. However, oxygen is another matter in fresh poultry food.

In carbon dioxide modified atmosphere packaging technology, carbon dioxide is an important gas used to protect food. It has a strong inhibitory effect on mold and enzymes, and has a "toxic" effect on aerobic bacteria, but it has poor effects on yeast and red aspergillus. Taking Cladomyces, Aspergillus, Penicillium softening, and Aspergillus as examples, when the concentration of carbon dioxide reaches about 10%, the reproduction rate of the first three shows a clear downward trend; The reproduction rate of Aspergillus was lower than 5%, while the slope value of Aspergillus was significantly slowed down after the concentration reached 10%, and the inhibition effect of the concentration on its reproduction rate was limited.

Nitrogen. Nitrogen itself has no inhibitory effect on the growth of microorganisms in any fresh food in modified atmosphere packaging, that is, it has no functions such as freshness preservation and antisepsis, and at the same time it is harmless to the food itself and will not accelerate its deterioration rate. The function of nitrogen here is reflected in two points: 1) fully reduce the residual oxygen in the gas components inside the packaging. 2) Concrete "DuPont's law": if carbon dioxide is easily absorbed by the moisture and fat in the food and the package becomes soft and collapsed, nitrogen can be used as a filler to make the sealed sales package visually fuller, more beautiful and upright Wider, so that it can attract consumers' attention faster in the sales process, generate a desire to buy, and achieve the effect of promoting sales. In addition, there are a few points to add: 1) It is impossible to achieve an absolutely oxygen-free environment inside the package. 2) The effect of carbon dioxide on fresh food preservation is limited. 3) Therefore, the actual application process of the modified atmosphere packaging scheme for fresh food often needs to be combined with the cold chain (relying on gas and low temperature environment) to achieve a more ideal effect.

Artificial modified atmosphere packaging technology

First of all, the key to gas composition is to maintain an environment with high concentrations of carbon dioxide and low concentrations of oxygen (generally 1%-6%). Low-concentration oxygen can inhibit the respiration intensity of fruits and vegetables without producing anaerobic respiration (fermentation); high-concentration carbon dioxide (generally 1%-12%, spinach, tomato up to 20%) can passivate its respiration, but once the ratio Exceeding the standard will lead to "poisoning" and spoilage of plant cells, so the specific ratio plan depends on the characteristics of fruits and vegetables. In addition, the reduction of storage temperature is also beneficial to the slowing down of the respiration intensity of fruits and vegetables, but generally it should not be lower than 0°C; otherwise, the phenomenon of "chilling injury and freezing injury" of fruits and vegetables is also an important reference index for temperature control.

Compared with man-made, natural modified atmosphere packaging technology has a higher utilization rate of nature. The key lies in the performance of selective breathable film, which is characterized by the use of non-active filling. Using the respiration of fruits and vegetables and the selective permeation (two-way) of different gases by the film, an internal environment with high concentration of carbon dioxide and low concentration of oxygen is automatically formed. Specific process: After the packaging is completed, due to the respiration of fruits and vegetables, the internal oxygen concentration decreases and the proportion of carbon dioxide increases, which limits respiration. Subsequently, when the internal carbon dioxide concentration is too high, the selective permeation function of the film (its ability to permeate carbon dioxide is 5 to 10 times greater than the ability to permeate oxygen) will permeate more internal carbon dioxide, and at the same time penetrate a small amount of external oxygen, to maintain the balance of the concentration of the internal gas components to achieve the freshness preservation effect. Film materials commonly used in modified atmosphere packaging must have good gas barrier and moisture barrier properties to maintain the best gas composition and concentration inside. In addition to the above two points, the requirements for material performance mainly include heat-sealing properties (high heat-sealing strength and easy heat-sealing to ensure sealing strength); prevent damage during the process); transparency (the contents can be seen through the film material, providing services for link inspection and sales); other required performance (according to the characteristics of fresh food to determine whether the material has properties such as oil resistance and fragrance retention) . The selective permeation of natural modified atmosphere packaging materials here is also related to film thickness and temperature, and the general law is

To sum up, the prerequisites for the practical application of modified atmosphere packaging:

1) Grasp the properties and changes of fresh food inside to determine the gas composition and concentration;

2) Control the effective storage temperature of food;

3) Applicable to different fresh foods and gas compositions Materials required.

Post time: Nov-30-2022